Industrial Powder Coating Powder

Product Details:

- Standard Normal

- Grade First Class

- Physical Form Powder

- Click to View more

Industrial Powder Coating Powder Price And Quantity

- 100 Kilograms

- 240 INR/Kilograms

Industrial Powder Coating Powder Product Specifications

- Powder

- Normal

- First Class

Industrial Powder Coating Powder Trade Information

- Cash Advance (CA)

- 5000 Kilograms Per Month

- 10 Days

- All India

Product Description

A form of dry powder used in the powder coating process for industrial applications is referred to as industrial powder coating powder. It is a finely ground mixture of resins, pigments, fillers, and other additives designed to give various metal surfaces a long-lasting and beautiful finish.

The following are some essential characteristics and factors pertaining to industrial powder coating powder:

1. The qualities of the coating, such as adhesion, flexibility, chemical resistance, and UV stability, are determined by the formulation of the industrial powder coating powders with certain resin systems. Additionally, the composition contains fillers to improve the coating's qualities and pigments to provide colour.

2. Application Techniques: Electrostatic spray guns or fluidized bed systems are frequently used to apply industrial powder coating powder. Before being dried in an oven, the powder particles are charged and sprayed onto the surface, where they cling electrostatically.

3. Curing: After being coated, the item is put through a curing process in a specialised oven. The heat melts and flows the powder, generating a continuous coating that chemically crosslinks and hardens to produce a long-lasting finish.

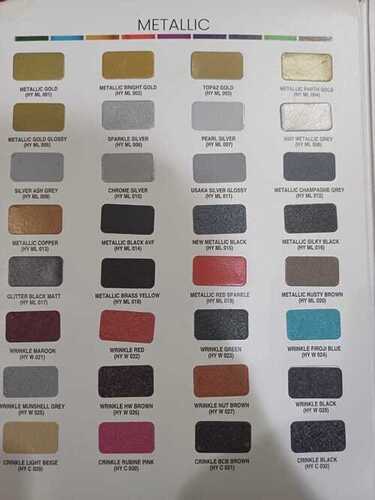

4. Smooth, textured, metallic, and special effects finishes are just a few of the many finish options that industrial powder coating powders have to offer. These finishing options can be altered to satisfy certain design specifications and aesthetic preferences.

5. Industrial powder coating powders provide the following performance characteristics: good resistance to impact, abrasion, chemicals, and UV damage. They are appropriate for industrial applications that call for high-performance coatings because they provide a long-lasting finish that can endure harsh environments.

6. The powder coating procedure is regarded as an environmentally beneficial coating method. Industrial powder coating powders typically produce little waste, little volatile organic compound (VOC) emissions, and no solvents. Powder waste can be reduced by recovering and reusing it.

Several different industries, including the automotive, aerospace, building, furniture, appliance, and metal fabrication, employ industrial powder coating powders. They are used on a variety of metal substrates, including galvanised surfaces, steel, and aluminium.

Specific performance criteria, colour possibilities, surface preparation requirements, compatibility with coating equipment, and curing processes are all things to keep in mind when choosing an industrial powder coating powder.

In general, industrial powder coating powders offer metal surfaces increased protection and visual appeal while also being a long-lasting, appealing, and ecologically friendly coating solution.

Specification

|

Brand |

Prominent |

|

Curing Emt |

190 |

|

Usage/Application |

Metal |

|

Finish |

Glossy, Satin, Matt, Pure Polyster |

|

Categories |

Regular Solid Colors |

|

Packaging Size |

10 Kg |

|

Packaging Type |

Corrugated Box |

|

Shelf Life |

6 Month |

FAQ

1. How do you define industrial powder coating powder?

Ans - A dry powder known as industrial powder coating is used to coat metal surfaces with a long-lasting, aesthetically pleasing finish. It is an excellent option for shielding surfaces from the environment because it is resistant to corrosion, abrasion, and discoloration.

2. What kind of materials can be coated using industrial powder coating powder?

Ans - Aluminium, galvanised steel, and wrought iron are just a few of the materials that can be coated with industrial powder coating powder. Additionally, it can be used on a variety of metals, such as epoxy-coated steel, stainless steel, and aluminium alloys.

3. What is the mechanism of industrial powder coating powder?

Ans - With the aid of an electrostatic spray cannon, the powder is applied to the material's surface. The powder particles stick to the material's surface as a result of the electrical field the cannon generates. After the material has been heated to a specific temperature, the powder fuses to form a hard, long-lasting finish.

4. For how long does Industrial Powder Coating Powder remain effective?

Ans - Depending on the material and application, industrial powder coating powder often lasts up to 15 years or longer. This kind of powder coating offers great corrosion protection and is extremely resistant to many dangerous elements when properly applied and cured.

5. What advantages can industrial powder coating powders offer?

Ans - Using industrial powder coating powder instead of conventional liquid coating has a number of benefits. It is perfect for outdoor applications because it is resistant to fading, cracking, and scratching. Additionally, it doesn't easily chip or flake off the surface and is environmentally safe.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese